Your inspectors (building, electrical, fire, environmental, worker safety, etc.) are responsible for making sure that your spray booth and processes are up to code. They are generally very interested in seeing your company prosper, but they are charged with making sure that the spray booth does not negatively impact the chance of a fire, worker injury or environmental issues.

This can seem complex and overwhelming when building a new spray booth. Here are some notes to make this easier.

Know your building:

-Total volume of building (floor space X height of ceilings)

-Building and floor materials

-Distance to nearby walls (should be at least 36”)

-Distance to electrical wiring and controls

-Proximity to property lines and other buildings

-Distance to spark-producing processes, like welding or grinding

-Escape routes for fires and other emergencies (aka egress)

Know your project:

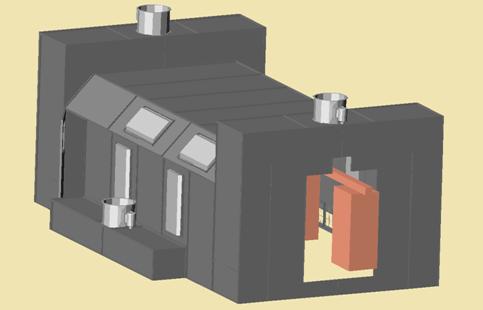

-Obtain drawings and specifications from the spray booth manufacturer

-Have contractor information for electrical/fire/ducting

-Be prepared to give information about building the spray booth and subcontracting specific processes

Know your process:

-Obtain MSDS sheets for materials to be sprayed

-Be prepared to provide a plan for storage/mixing/waste management/training.

Know your plan:

-talk to your local inspectors before buying the spray booth (Do you need ETL certification? Are your inspectors influenced by other local spray booth incidents)

-submit a simple site plan (This goes a long way with letting your inspectors feel that you are open with them and wish to meet all code requirements.)

Know your support:

-Standard Tools can help you by providing information about the product and general code information.

-More information is available on the Tools USA blog by searching ‘permit’ or by contacting us at 800-451-2425.

For more information on paint booths please visit us at www.toolsusa.com.